Glass bottles are a popular choice for packaging various products, including beverages, cosmetics, and pharmaceuticals, due to their aesthetic appeal and ability to preserve contents effectively.

However, the fragility of glass poses a challenge when it comes to bottle boxes packaging and transportation. To ensure glass bottles arrive intact and prevent breakage, it is crucial to implement proper packaging techniques.

Choose Appropriate Packaging Materials

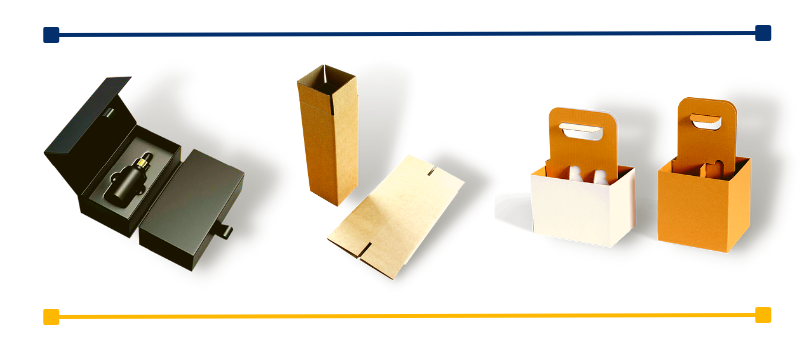

Selecting appropriate packaging materials is the first step in safeguarding glass bottles. Consider using corrugated cardboard boxes with adequate thickness and strength to withstand external impacts during transit.

You must opt for materials such as bubble wrap, foam inserts, or dividers to provide cushioning and prevent bottles from coming into direct contact with each other or the box’s walls.

Individual Bottle Wrapping

Individually wrapping each glass bottle adds an extra layer of protection. Wrap the bottles with bubble wrap or foam sleeves to provide a cushioning barrier that absorbs shocks and minimizes the risk of contact damage.

Secure the wrapping with tape to ensure it stays in place during handling and transportation. High quality small bottle packaging boxes play an important role in keeping bottles safe.

Use Dividers or Partitions

When packaging multiple glass bottles in a single box, consider using dividers or partitions to create individual compartments. These dividers prevent bottles from clashing against each other and provide additional stability.

Cardboard or foam inserts can be customized to fit the bottle shape and securely hold them in place within the box.

Fill Empty Spaces

To minimize movement within the packaging box, fill any empty spaces with cushioning materials like packing peanuts, air pillows, or crumpled paper. This helps prevent bottles from shifting and colliding during transit.

It is essential to ensure a snug fit without excessive compression to maintain the integrity of the packaging.

Label Fragile

Clearly mark the packaging as “Fragile” or “Handle with Care” to alert handlers to exercise caution. This labeling serves as a reminder to treat the package delicately and avoid rough handling. Place the labels on multiple sides of the box to ensure visibility from various angles.

Strengthen Box Sealing

Proper sealing of the packaging box is critical to secure the glass bottles inside. Use high-quality packaging tape to seal all edges and seams of the box. Reinforce the bottom of the box with additional layers of tape to provide extra strength and stability.

Test and Evaluate

Conduct thorough testing and evaluation procedures to ensure the chosen packaging design and materials effectively protect the glass bottles. Simulate various transportation scenarios to assess the packaging’s resilience against potential shocks, vibrations, and drops.

Make adjustments as necessary to enhance the packaging’s protective capabilities.

Creating Secure Compartments for Glass Bottles

When packaging multiple glass bottles in a single box, utilizing dividers or partitions is an effective strategy to provide added protection. Dividers create individual compartments for each bottle, preventing them from clashing against one another and minimizing the risk of breakage.

Customized Inserts

The custom bottle packaging also comes in dividers or partitions to fit the specific shape and size of the glass bottles. This customization ensures a snug fit, preventing excessive movement and reducing the chances of impact-related damage.

Cardboard or foam inserts can be cut or molded to match the bottle dimensions and securely hold them in place within the box.

Material Selection

Choose materials with cushioning properties to provide an additional layer of protection. Foam inserts, such as polyethylene or polyurethane foam, offer excellent shock absorption and can be shaped to cradle the bottles securely.

Corrugated cardboard dividers are another option, providing both stability and cushioning.

Reinforce Stability

Enhance the stability of the dividers by securing them firmly within the packaging box. Use adhesive or tape to attach the dividers to the walls of the box, ensuring they remain in their designated positions during transit.

This reinforcement prevents the dividers from shifting or collapsing, maintaining the integrity of the individual compartments.

Adjustable Dividers

In most custom bottle boxes you will find adjustable dividers or partitions that can accommodate bottles of varying sizes. This flexibility allows for versatility in packaging different bottle shapes and sizes without compromising on the level of protection. Adjustable dividers can be repositioned or removed as needed, ensuring a secure fit for every bottle.

Testing and Optimization

Conduct thorough testing to validate the effectiveness of the divider or partition system. Simulate transportation conditions and evaluate the performance of the dividers in preventing bottle-to-bottle contact and minimizing movement. Optimize the design based on testing results to ensure maximum protection and stability.

By implementing dividers or partitions, companies can create secure compartments within the packaging box, reducing the risk of glass bottles colliding and breaking, thanks to custom bottle boxes.

Customized inserts, careful material selection, stability reinforcement, adjustable dividers, and rigorous testing contribute to an optimized packaging solution that effectively protects the fragile glass bottles throughout the transportation process.

Safely packaging glass bottles is essential to prevent breakage and ensure the integrity of the contents during transportation.

By selecting appropriate packaging materials, individually wrapping each bottle, using dividers or partitions, filling empty spaces, labeling as fragile, and strengthening box sealing, companies can significantly reduce the risk of glass bottle breakage. You can also contact custom printed bottle boxes wholesale dealers to buy bulk quantity bottles.

Implementing these best practices will help protect fragile glass bottles and ensure they arrive intact, satisfying customers and preserving the quality of the packaged products.